Sintered Brake Pads and Clutch Materials for The Industrial Industry

Our high-energy brake materials, low-wear friction materials, and sintered brake pads are popular in the industrial market, which also boasts plenty of GMP success stories.

One of our customers, a manufacturer of a battery-powered nailer came to us looking for a clutch material that could meet some challenging stipulations. Not only does the nailer spin at 10,000 rpm, generating a very high instantaneous-energy demand, but the clutch has a one-of-a-kind mechanical configuration, thus the friction material also had to have just the right amount of slip, and wear was a serious concern. GMP met all these requirements with a high-energy, low-wear friction material for the clutch.

GMP not only solves such challenges, but is also committed to both quality and excellent customer service. Recently, a forklift manufacturer that could never seem to get satisfactory customer service from their vendor turned to GMP Friction Products. We supplied them with a friction material that outperforms what they had been using, and we continue to meet their increasing demand. We have a great relationship with this customer, who appreciates our courteous customer service, especially since they said their previous vendor treated them as “a little fish in a big pond.”

Additional GMP components in this market include spring-applied, hydraulic-release brakes, electromagnetic clutches, overload clutches, torque-limiting clutches, and dry brakes, which appear on man lifts, cranes, hoists, winches, material-handling and other industrial equipment.

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141

Learn More About Sintered Metallic Brake Pads and Clutches in the Industrial Market

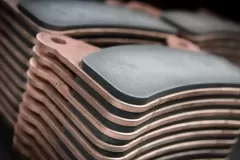

Sintered metallic brake pads and clutches are highly valued in the industrial market for their exceptional durability and performance under demanding conditions. These components are manufactured through a process of compressing and sintering metallic powders, which creates a dense, robust material capable of withstanding high levels of stress and heat. The sintering process often involves metals such as copper, iron, and graphite, which are chosen for their superior frictional properties and thermal conductivity. This makes sintered metallic brake pads and clutches particularly suitable for heavy-duty industrial applications where consistent braking performance and efficient power transmission are essential.

In various industrial sectors, the adoption of sintered metallic brake pads and clutches translates to significant operational benefits. These components offer outstanding wear resistance and a longer lifespan compared to traditional organic or semi-metallic options, which is critical for machinery that operates continuously under high loads. The superior heat dissipation properties of sintered metallic materials reduce the risk of overheating and brake fade, ensuring reliable performance and minimizing downtime. Furthermore, their ability to maintain functionality in harsh environments—such as those involving exposure to oil, water, and debris—makes them ideal for a wide range of industrial applications. By enhancing the reliability and efficiency of industrial machinery, sintered metallic brake pads and clutches contribute to increased productivity and reduced maintenance costs.