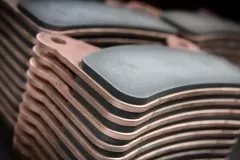

Sintered Brake Pads and Clutch Solutions For The MotorSports Industry

Whether it’s oval track, road course, or dragstrip racing, motorsports are yet another market where GMP Friction’s materials shine. Our specially formulated sintered bronze friction material enables our dry performance clutch discs, sintered brake pads, high-performance clutch components, high-energy brake materials, and other motorsports products to meet the grueling environment of competition.

For instance, a stock race car requires a high-performance clutch that can bear the relentless and enormous demands put on it. Several different clutch companies were finding that the performance of their suppliers’ friction materials was not consistent, nor were these suppliers meeting all their volume needs. Both motorsports clutch companies came to GMP Friction Products, and we now supply them—dependably and punctually—with high-energy friction materials that have excellent and reliably consistent performance, all at a competitive price.

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141

Learn More About Sintered Metallic Friction Materials in the Motorsports Industry

Sintered metallic friction materials have revolutionized the motorsports industry by significantly enhancing the performance and durability of braking systems. These materials, made from powdered metals that are compacted and heated to create a solid mass, offer superior thermal stability and resistance to wear compared to traditional organic or semi-metallic brake pads. In high-performance motorsports, where brakes are subjected to extreme temperatures and forces, sintered metallic friction materials maintain consistent performance and reliability. This consistency is crucial for drivers, as it ensures predictable braking response and reduces the risk of brake fade during intense racing conditions. The enhanced durability of these materials also means longer service intervals, reducing the frequency of brake changes and thus improving overall vehicle uptime during competitions.

Moreover, the high friction coefficient of sintered metallic materials provides excellent stopping power, which is essential for the demanding braking requirements in motorsports. This characteristic allows for more aggressive driving and shorter braking distances, giving drivers a competitive edge. The ability of these materials to function effectively in both wet and dry conditions further adds to their versatility, making them a preferred choice in various racing disciplines, from Formula 1 to endurance racing. Additionally, the advancements in manufacturing techniques have enabled the customization of sintered metallic friction materials to suit specific racing needs, ensuring optimal performance for different vehicles and track conditions. Overall, the adoption of sintered metallic friction materials in motorsports has played a pivotal role in advancing the technology and safety standards of high-speed racing.