High Energy, Low Wear Friction Materials Solutions For The Mining Industry

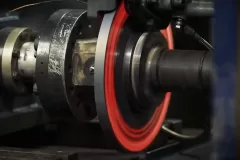

Our products are well represented in the mining market around the world. This is because with the help of GMP Friction Products, dry brakes, wet wheel brakes, snubber discs, wet disc brakes, and multi-disc brakes can withstand the harsh conditions of the mining environment.

In mining, reliability is even more important than in other industries, since down-time and repairs add up to even greater costs when equipment is far underground. GMP Friction’s dependable products help keep dump trucks, front-end loaders, drag lines, electric rope shovels, and other equipment running in the mines.

GMP’s skill for creating unique products is as beneficial in mining as in all our other markets. For instance, a brake manufacturer designed a proprietary brake for underground mining vehicles, as an improvement on the conventional caliper brake. They couldn’t find a friction material that could endure the stresses of the mining environment, however; the friction materials of one manufacturer after another failed. Convinced they had a winning design, they persisted and approached GMP. In collaboration with them, we developed a new friction material ideal for this demanding application and with just the right grooving. Not only is our new customer happy, but their customers are happy too, as this means significant savings for the mining companies in greatly reduced downtime and brake replacement costs.

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141

Learn More About Sintered Metallic Brake Pads and Clutches in the Mining Industry

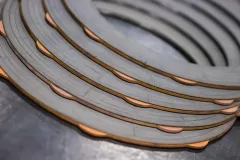

Sintered metallic brake pads and clutches are essential components in the mining industry, renowned for their durability, high performance, and reliability under extreme conditions. These components are made by compressing metallic powders and sintering them at high temperatures, resulting in a dense and robust material that can withstand the harsh environments encountered in mining operations. The sintering process allows for the inclusion of various metals, such as copper, iron, and graphite, to enhance the frictional properties and thermal conductivity of the brake pads and clutches. This makes them particularly effective in heavy-duty machinery, where consistent braking performance and efficient power transmission are critical for safety and productivity.

In the mining industry, the use of sintered metallic brake pads and clutches ensures superior wear resistance and a longer lifespan compared to traditional organic or semi-metallic counterparts. These attributes are crucial in environments where machinery is subject to continuous operation and significant mechanical stress. Sintered metallic components offer excellent heat dissipation, reducing the risk of overheating and brake fade, which can lead to equipment failure and costly downtime. Additionally, their ability to perform reliably in wet and dirty conditions makes them ideal for mining applications, where exposure to mud, water, and debris is common. By maintaining optimal performance in such challenging conditions, sintered metallic brake pads and clutches help enhance the overall efficiency and safety of mining operations.