Dry Braking, Dry Clutching Solutions For The Military

All five branches of the U.S. military—the Army, Navy, Air Force, Marines, and Coast Guard—rely on the rugged and resilient products of GMP Friction (CAGE 01141). We support U.S. military equipment on land, on the sea, and in the air because our exceptionally resilient, high-energy, low-wear friction materials are designed to stand up to most severe, most aggressive, most abusive environments.

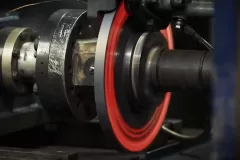

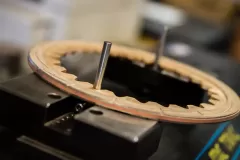

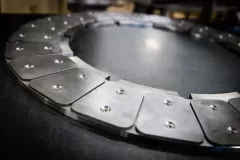

In addition, the widest diversity of GMP Friction products is found in the military market. Our components support steer clutches, transmission clutches, generator clutches, dry brakes, underway replenishment winches, armament support equipment, electromechanical actuating systems, cargo winches, rescue winches, aircraft arresting gear components, and more. Our products are used on tanks, tactical vehicles, aircraft, airbase land equipment, armored personnel carriers, and Navy ships.

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141

Learn more about Sintered Metallic Brake Pads and Clutches in the Military

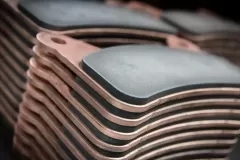

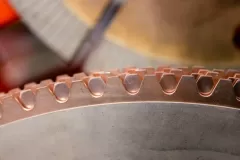

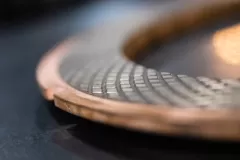

Sintered metallic brake pads and clutches are commonly utilized in military vehicles and equipment due to their exceptional durability and performance under extreme conditions. These components are manufactured by compressing metal powders at high temperatures, resulting in a dense, solid material with excellent thermal conductivity and resistance to wear. In military applications, where vehicles are subjected to rigorous use in harsh environments, such as combat zones or off-road terrain, the reliability and longevity of braking and clutch systems are paramount. Sintered metallic pads and clutches offer superior heat dissipation capabilities, allowing them to maintain consistent performance even during prolonged and intense use, such as repeated braking during high-speed maneuvers or towing heavy loads.

Moreover, sintered metallic brake pads and clutches provide enhanced stopping power and control, crucial for military vehicles operating in diverse conditions, including various weather conditions, rugged terrain, and emergency situations. The ability to withstand high temperatures without sacrificing performance ensures that military vehicles can maintain optimal braking efficiency even in demanding scenarios, such as long descents or sudden stops in combat zones. Additionally, the robust construction of sintered metallic components contributes to their resilience against wear and tear, reducing the need for frequent replacements and maintenance, which is particularly advantageous in military operations where reliability and readiness are essential. Overall, the use of sintered metallic brake pads and clutches in military vehicles helps to ensure operational effectiveness and safety in challenging environments.