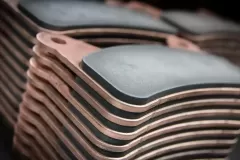

Sintered Brake Pads, Dry Braking Applications

For Diverse and Demanding Applications

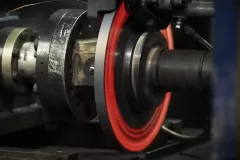

GMP Friction’s extensive variety of dry brake friction materials meet diverse and demanding applications, whether they require a high coefficient of friction or the capability to tolerate extreme pressure or extreme temperatures.

As a result, such heavy-duty markets as aerospace, agriculture, construction, industrial, military, mining, motorsports, and powersports rely on our high-energy brake materials and wide portfolio of sintered brake pads. Globally, our resilient dry braking materials withstand the severe abuse they encounter, whether it be in winches, cranes, race cars, tractors, logging equipment, or aircraft arresting systems.

Our sintered metallic brake pads can tolerate environmental conditions that organic and semi-metallic pads simply cannot.

What Are Sintered Brake Pads?

A sintered brake pad is a specialized type of brake pad used in automotive braking systems. It is manufactured through a process called sintering, where various metal and non-metallic particles are compacted and heated to high temperatures until they fuse together. This results in a dense and durable composite material with enhanced friction properties, making sintered brake pads well-suited for high-performance and heavy-duty applications.

The sintering process allows the pad to withstand extreme temperatures and intense mechanical forces, ensuring consistent braking performance even under demanding conditions. Sintered brake pads are known for their excellent heat dissipation, reduced fading, and improved braking efficiency, making them a popular choice among enthusiasts, racing teams, and vehicles that require reliable stopping power.

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141