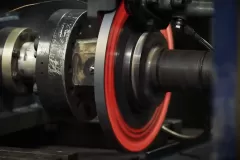

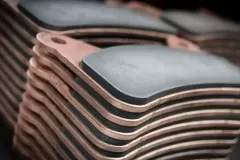

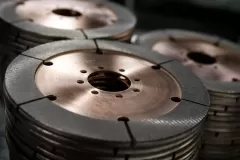

Wet and Dry Clutch, Sintered Brake Pad Solutions For The PowerSports Industry

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141

Sintered Metallic Friction Materials in the Powersports Industry

Sintered metallic friction materials are widely used in the powersports industry, where vehicles such as motorcycles, ATVs, snowmobiles, and other off-road machines demand high-performance braking systems. These materials are created by fusing metal powders under heat and pressure, resulting in a durable, heat-resistant compound that can withstand the rugged conditions often encountered in powersports. Due to their ability to operate effectively at high temperatures without fading, sintered metallic friction materials offer consistent braking performance, even in extreme conditions such as muddy, wet, or dusty environments. This reliability makes them particularly suited for powersports vehicles that frequently face unpredictable terrains and require dependable stopping power for safety.

In addition to their resilience in harsh environments, sintered metallic friction materials provide excellent durability and longevity, reducing the frequency of brake replacements. Powersports enthusiasts benefit from this extended service life, as it minimizes downtime and maintenance costs while ensuring optimal performance on trails, tracks, or snow-covered landscapes. The high friction coefficient of these materials also translates to superior braking power, enabling more confident and controlled rides, especially during high-speed or technical maneuvers. As powersports vehicles continue to evolve with higher speeds and more advanced technology, sintered metallic friction materials remain a critical component in delivering the necessary safety and performance standards for both recreational riders and competitive racers alike.