Sintered Friction Clutch Materials For The Marine Industry

The dependability of GMP Friction Materials’ wet multi-plate clutches, marine transmissions, and power take-offs can result not only in saving money, but also in saving lives. A marine transmission manufacturer found out the hard way that the adhesive on the paper friction material they were using could not hold up to all the conditions of the marine environment, resulting in transmission failure and ships adrift—a situation both costly and dangerous. Switching to GMP’s sintered friction materials, which never experience bond failure, has solved this problem. As our products can tolerate extraordinary abuse, vessels are much more likely to make their way back to land even if the transmission malfunctions.

The marine market has also witnessed GMP’s swift resourcefulness. When an oil rig’s clutch plates were destroyed and the usual supplier could not replace them in time, the drilling rig company came to GMP Friction. Though we had never made this particular part before, our engineering and manufacturing professionals rose to the occasion and got the clutch plates to the rig in record time, saving the company hundreds of thousands of dollars a day.

Call Today: 330.633.1226

ISO 9001:2015 Certified

CAGE CODE: 01141

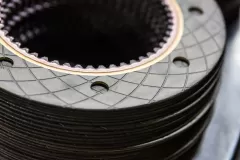

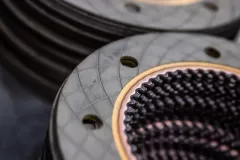

Sintered Metallic Friction Materials in the Marine Industry

Sintered metallic friction materials have gained prominence in the marine industry due to their exceptional durability and resistance to the harsh environments encountered on the water. Boats, yachts, and other marine vessels require reliable braking and clutch systems, especially in conditions where exposure to saltwater, humidity, and extreme temperatures can lead to accelerated wear. Sintered metallic materials, made by compressing and sintering metal powders, offer excellent corrosion resistance and maintain their performance under these tough conditions. This makes them ideal for use in marine applications, where long-lasting and low-maintenance components are essential for safety and efficiency, particularly in high-performance watercraft that demand quick and reliable stopping power.

Additionally, the heat dissipation properties of sintered metallic friction materials make them well-suited for marine environments where sustained operation can generate significant friction-induced heat. These materials ensure consistent performance without the risk of overheating or brake fade, even during prolonged use. This characteristic is especially important for larger vessels or high-speed boats that require precise control during docking, maneuvering, or emergency stops. Their robustness, combined with the ability to perform reliably in both fresh and saltwater environments, has made sintered metallic friction materials a key technology in advancing the reliability and safety standards of marine braking systems and clutches.